Current & Recent Projects

56 1/2" Bradbury Upright (F.G. Smith) #27867 (1897)

56 1/2" Bradbury Upright (F.G. Smith) #27867 (1897)

Vintage mahogany Cabinet. Built in 1897. Restored in Fall 2021 for the owner in Foley, MN.

IMPROVEMENTS:

Sound Board, Pins, Strings--Remove strings, tuning pins, plate. Repair & refinish soundboard. Restring & repin.

Recondition Action & Pedal Board—Install new hammers, damper felts, butt leather, jack springs, key bushings, underkey punchings. Tighten all action screws, replace other defective parts as needed. Dismantle & rebuild pedals, posts, levers.

Complete Regulation & Tuning—All adjustments to ensure that piano plays like new, tune to A-440.

Complete Refinishing--Dismantle music rest, fallboard, legs, panels: prepare exterior surfaces for refinishing. Remove pedals & backplate for nickel-plating. Complete refinishing, install new fallboard decal.

|

A1 - Beautiful cabinet, very little damage |

|

|

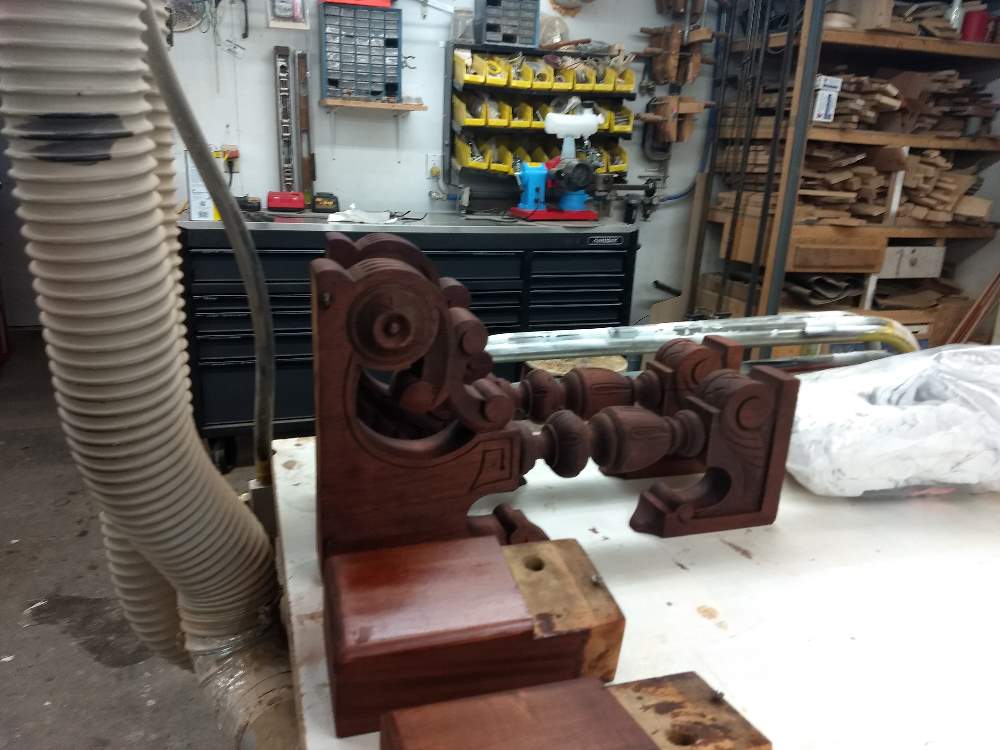

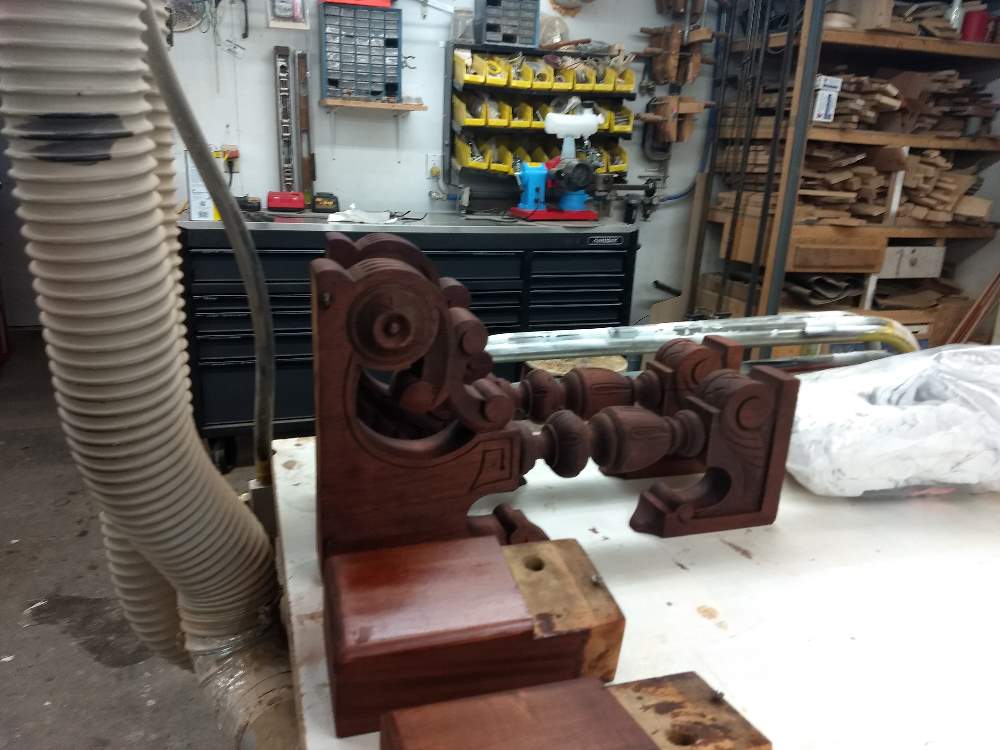

A2 - Ornate music rest |

|

|

A3 Hinged lid |

|

|

A4 - Veneer damage on left foot |

|

Selected pictures of the step-by-step improvement process

CLICK PICTURE FOR LARGER IMAGE, THEN CLICK "CLOSE" TO RETURN TO THIS PAGE

Original Manufacturer of this brand-name--Bradbury Piano Co., with F.G. Smith as superintendent.

Established--1861, by William B. Bradbury

Other brand-names used by this manufacturer--F.G. Smith, W.P. Haines, Winter & Co., F.C. Lighte, Lighte & Newton, Lighte-Newton & Bradbury, Lighte & Bradvury, Poole, Ivers & Pond.

From: Pierce Piano Atlas, 12th Edition (2008, Larry Ashley Publisher, Albuquerque, NM).

Note: To obtain the age of your piano and details about the manufacturer, click: Pierce Piano Atlas--"the world's most authoritative publication on piano manufacturers, past and present." To learn how a piano works and how to go about buying one, we encourage you to purchase The Piano Book.

A - EVALUATION

B - DISASSEMBLY, DESTRINGING, BOARD REPAIRS, RESTRINGING

|

A5 - Veneer damage on right foot |

|

|

A6 - Missing veneer at right top |

|

|

A7 - Veneer damage at front right corner |

|

|

A8 - A few replacement bass strings and large-size pins, new bridle tapes |

|

|

A9 - Pin torque about 20-25, needs restringing, repinning |

|

|

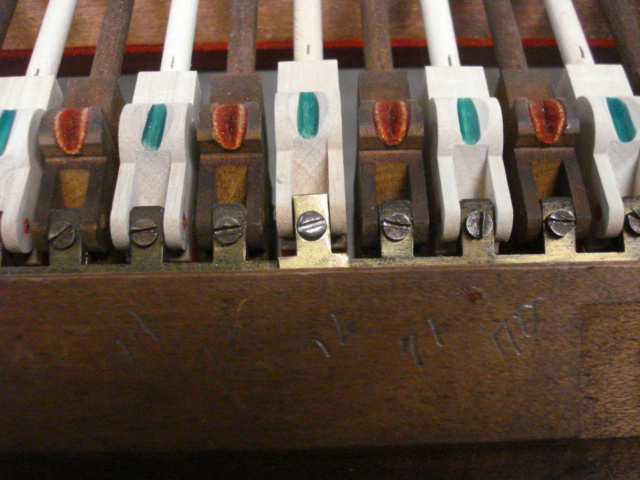

A10 - Needs new dampers, hammers, catcher leather, jack springs, underkey punchings, hammer rail cloth, & key cloth |

|

For contact information, go to the "Home Page"

"Before picture" - taken during evaluation

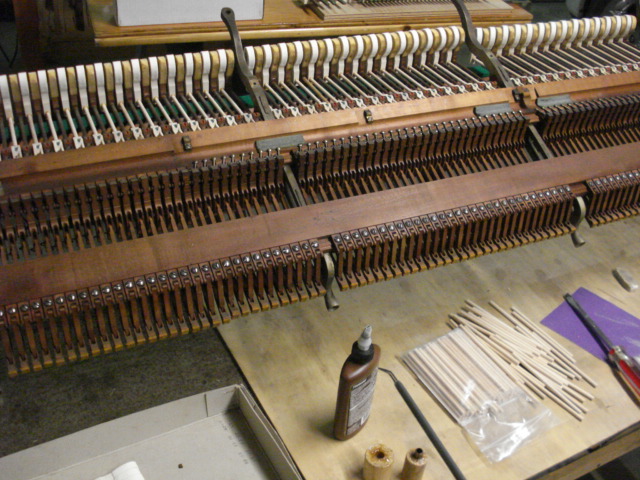

C - RECONDITIONING THE ACTION

|

B1 - Panels, Keybed, Pedalboard removed |

|

|

B2 - Left Foot reglued. |

|

|

B3 - Pedals & backplate cleaned, ready for nickle-plating |

|

|

B4 - New casters installed |

|

|

B5 - Left foot assembly re-glued to side-wall. |

|

|

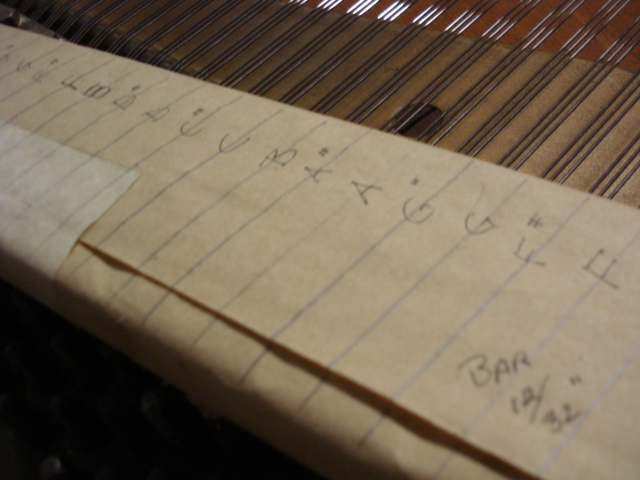

B6 - We prepared a stringing guide for the treble section, including heights of pressure bars and action brackets above the plate. |

|

|

B7 - Original bass strings removed, arranged in order on a soft wire. |

|

|

B8 - Bass strings packed for shipment to string-maker. |

|

|

B9 - Bass strings ready for shipment to string-maker |

|

|

B10 - Removing treble strings |

|

|

B11 - Removing tuning pins |

|

|

B12 - Plate screws & action brackets arranged on cardboard guide for ease in re-installation |

|

|

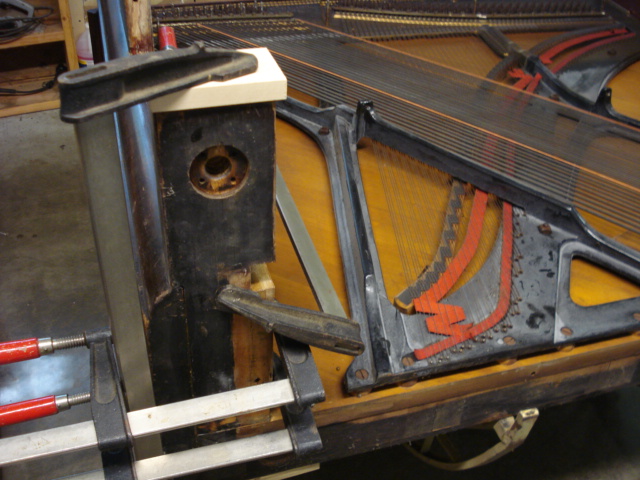

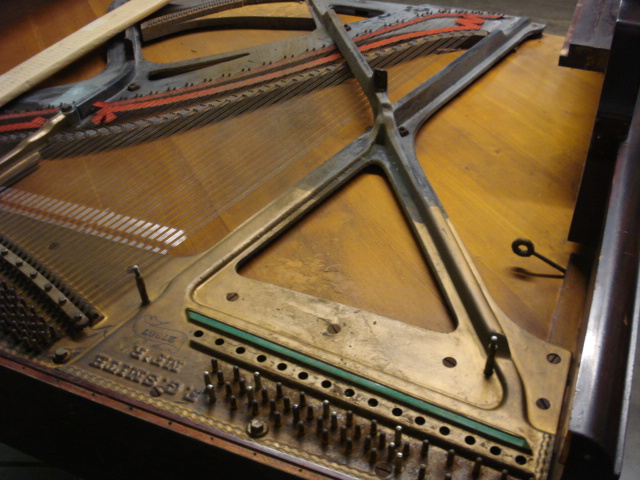

B13 - Plate lifted with winch, ready for repairs to board, bridges, pinblock |

|

|

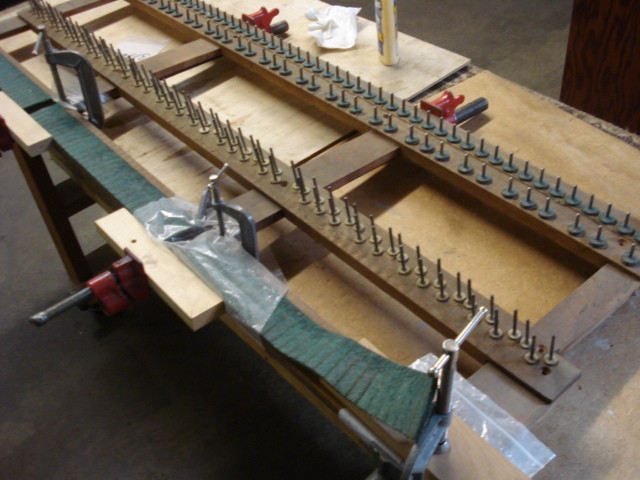

B14 - Glue & clamp upper frame and pinblock |

|

|

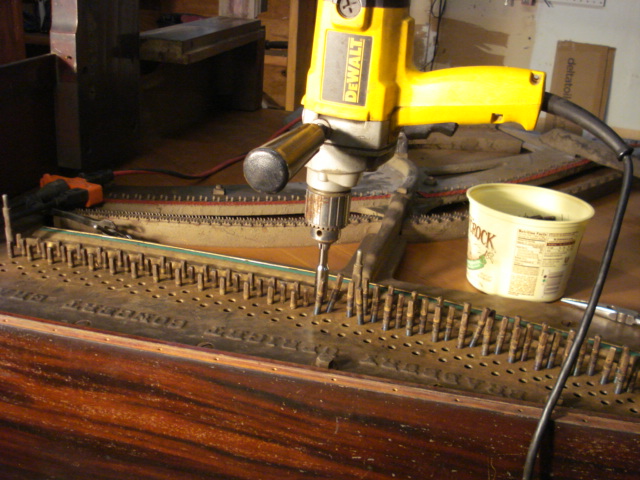

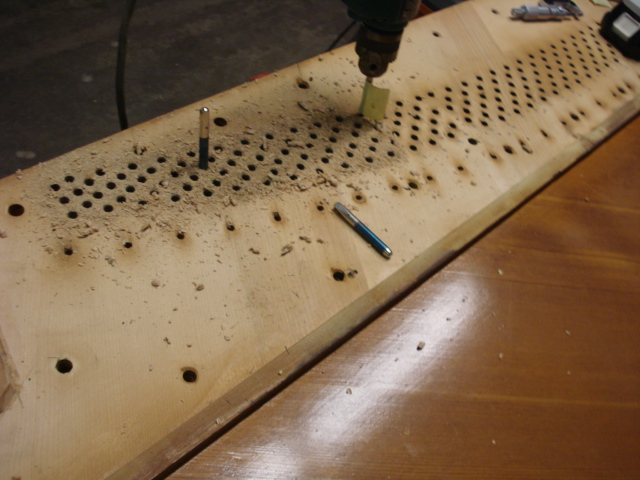

B15 - Increase tuning pin holes by a quarter inch for longer replacement pins |

|

|

B16 - Sand pinblock surface |

|

|

B17- Scrape and sand soundboard |

|

|

B18 - Repair treble bridge in two places |

|

|

B19 - Treble bridge repair |

|

|

B20 - Using electric heater and with the piano insulated with packing blankets, the soundboard is dried overnight to widen soundboard cracks |

|

|

B21 - Every open crack is shaped at a V angle with a shimming tool |

|

|

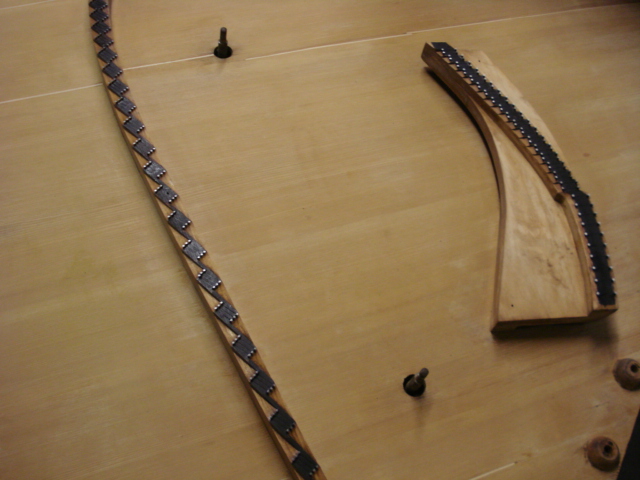

B22 - Soundboard shims are cut and glued in place |

|

|

B23 - Using a special chisel, tops of shims are cut so they're even with the soundboard surface |

|

|

B24 - Graphite is brushed on bridge surfaces between the bridge pins |

|

|

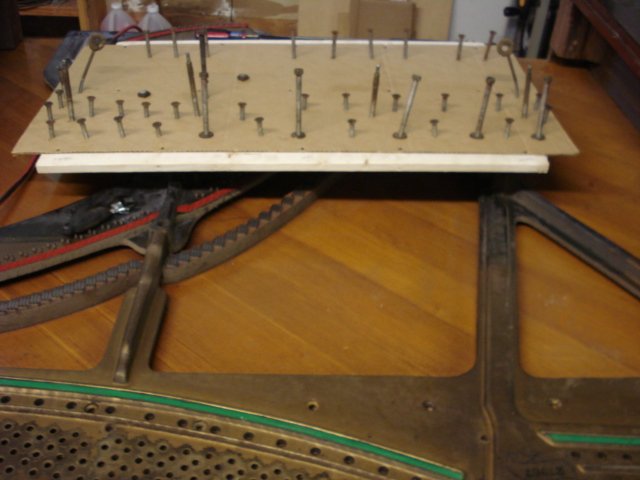

B25 - We drilled two test holes at the top treble end of the pinblock to check pin torque. We decided to replace original size 1 pins with size 3 pins. |

|

|

B26 - We cleaned the piano plate and slightly enlarged the pin-holes to accommodate larger-size tuning pins. |

|

|

B27 - The first coat of urethane was brushed onto the surface of the soundboard and bridges. |

|

|

B28 - After 3 coats of urethane, we winched the plate in position onto the piano frame |

|

|

B29 - With the plate bolted in position, we used the Klepac Chart to correct the stringing scale. |

|

|

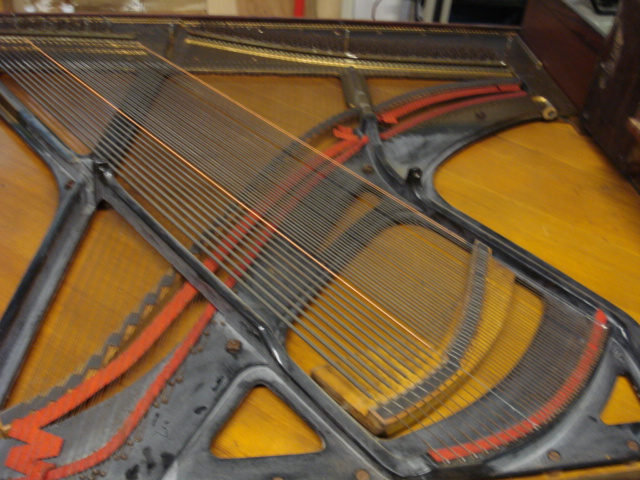

B30 - The treble section has been restrung and repinned, and the pressure bar has been installed. |

|

|

B31 - Using a pitch-pipe, we chipped up the pitch of all treble strings. |

|

|

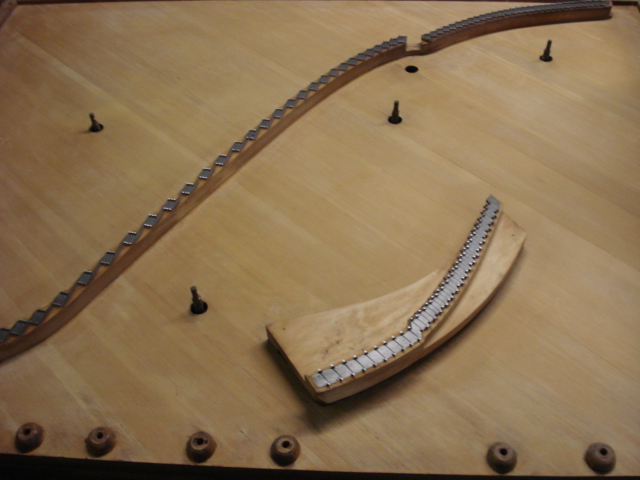

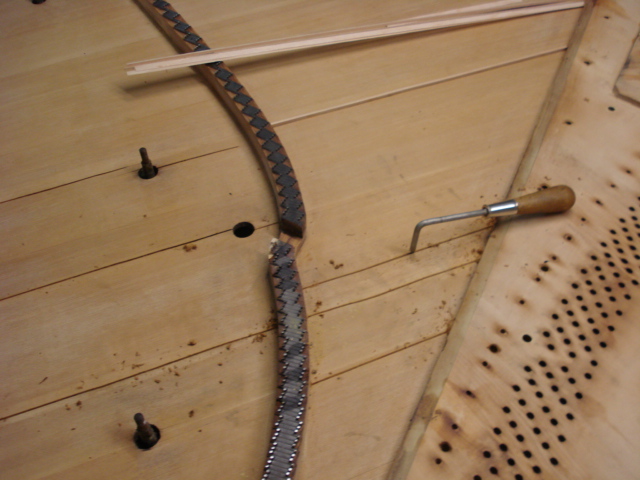

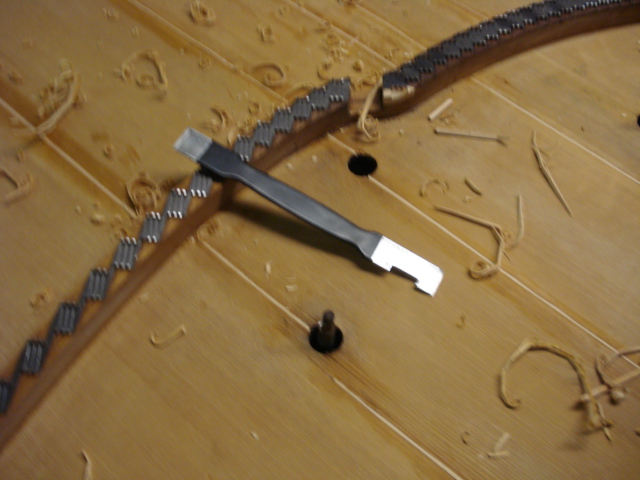

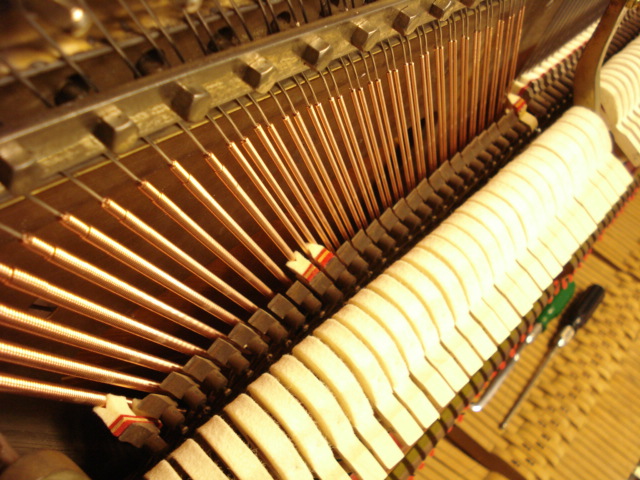

B32 - We installed stringing braid in the treble section. |

|

|

B33 - We restrung the bass section with new bass strings and installed stringing braid. |

|

|

B34 - Before cleaning and reconditioning them, we temporarily installed the keyboard and the action and tuned the piano, to ensure a stable tuning when the project is completed. |

|

|

B35 - The harp is packed, ready to be shipped to the refinisher |

|

|

B36 - Fifteen panels and parts facing the exterior of the piano are ready to be shipped to the refinisher |

|

|

C1 - We repaired unglued sections of the key frame. |

|

|

C2 - We cleaned the keyframe wood and the keypins, and installed new felt punchings. |

|

|

C3 - We cleaned the keys, keytops, and capstans with steel wool, and with the keys on the keyframe, we rough-regulated key heights and keydip. |

|

|

C4 - We removed the spring rail, sustain rods, regulating rail and the dampers from the action for close inspection of all action parts before deciding on replacement parts to order. |

|

|

D1 - The keybed, music desk hinge frame and lower panel have been stripped. |

|

|

D2 - The fallboard, bottom rail and lid have been stripped. |

|

|

D3 - The right leg and end blocks have been stripped. |

|

|

D4 - The cabinet exterior has been sanded, ready for stain |

|

|

D5 - The music desk and panels have been sanded and are ready for stain |

|

|

D6 - The legs and end blocks have been sanded |

|

|

D7 - The cabinet exterior has been stained |

|

|

D8 - The music desk has been stained |

|

|

D9 - The legs and end blocks have been stained |

|

|

D10 - The lid, music rest and fallboard components have been stained |

|

D - We partnered with Mike and Tammy Frank of Frank's Custom Furniture, Foreston, MN, for REFINISHING WORK on this project. Pictures in this section were taken in their shop.

E - After refinishing was completed, the piano and all refinished components were returned to our shop for FINAL ASSEMBLY, ACTION REGULATING, AND TUNING.

|

E1 - We installed the bottom board, keybed, and decorative legs, and we reconditioned and re-assembled the pedal mechanisms. |

|

|

E2 - We installed the keyframe, and glued new key cloth in place on the back rail. |

|

|

E3 - We installed the reconditioned action, and we assembled and installed the nameboard and fallboard assembly, and we regulated key heights just below the nameboard felt. |

|

|

E4 - We fine-regulated key heights using a straight edge, and we fine-regulated keydip to ensure consistent touch. |

|

|

C5 - We decided to order new hammers, shanks, and butts. We removed seven hammers to send to the hammer supplier as samples. |

|

|

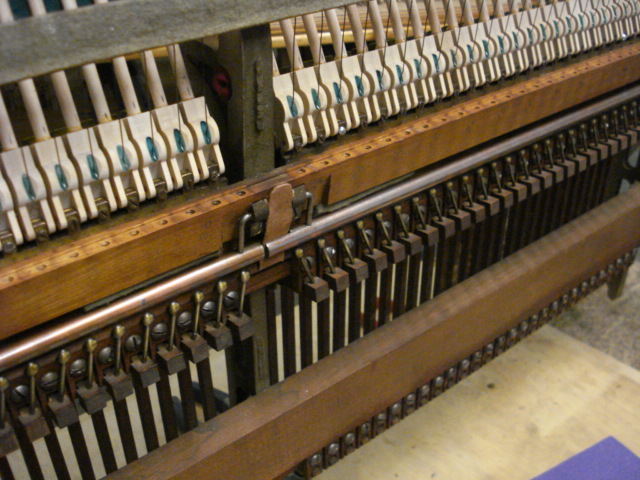

C6 - We cleaned and polished the sustain rod and the hammer rail, installed new hammer rail cloth, and replaced faulty hammer springs and regulating buttons. |

|

|

C7 - We refinished the pedal board, and we installed and re-bushed the newly nickel-plated pedals. |

|

|

C8 - We removed the old damper pads , cleaned the wooden and metal parts of the damper lever assemblies, and strengthened the damper flange springs. |

|

|

C9 - We repaired damaged locations on the brass rail to ensure tight fit for the hammer butts. |

|

|

C10 - We installed new even-numbered hammers and butts. |

|

|

C11 - We installed odd-numbered hammers and butts. |

|

|

C12 - We connected bridle tapes of the new hammer butts to the wippens and regulated back-checks. |

|

|

C13 - We re-installed the cleaned sustain rod system and replaced the felt bushing connecting the two rods. |

|

|

C14 - We re-installed the cleaned damper levers. |

|

|

C15 - We installed new treble damper felts. Bass damper felts will be installed as part of re-assembly after refinishing has been completed. |

|

|

E5 - We fine-regulated key spacing and tightened wobbly keys by turning under-key pins. |

|

|

E6 - We fine-regulated black key heights using a key height guage. |

|

|

E7 - We fine-regulated hammer-to-string alignment by heating and turning hammer heads and moving strings where needed. |

|

|

E8 - We fine-regulated letoff, sustain adjustment and spoons in treble section. |

|

|

E9 - We shaped and installed new damper felts at the ends of the bass section, then regulated sustain adjustment and spoons for newly installed bass dampers. |

|

|

E10 - We removed the action and, with the action on the workbench, we regulated the spoons and damper wires in the bass section. |

|

|

E11 - On the workbench, we also regulated damper wires and spoons in the treble section, as needed. |

|

|

E12 - With the action back in the piano, we installed the rest of the bass damper pads. |

|

|

E13 - We found that the pitch was almost a tone flat since installing and chipping the strings to pitch. Several pitch adjustments and tunings will be needed before delivery. |

|

|

E14 - We installed the lower panel, the fallboard assembly, including hinges, rubber buttons, and knobs. |

|

|

E15 - We installed the music desk, which swivels on hinges supported by a frame behind it. When the fallboard is opened, the bottom of the music rest swings outward. |

|

|

E16 - Close-up of the Bradbury decal and the middle keys. |

|

|

E17 - We assembled and installed the hinged lid, with black rubber buttons to protect the finished surfaces. |

|

|

E18 - Project finished! After one final tuning, it will be delivered to the owner. |

|

Close-up of new decal and keyboard

Project Finished! To be delivered after a final tuning