Current & Recent Projects

38" Knabe Studio #133816 (1946)

38" Knabe Studio #133816 (1946)

Traditional Mahogany Cabinet. Reconditioned in April, 2021 for the current owner in Clear Lake, MN.

|

A2 - Harp OK |

|

|

A3 - Lid Music Desk & Fallboard Removed |

|

|

A4 - Action Removed |

|

|

A5 - Underkey Punchings Worn |

|

IMPROVEMENTS:

Repin--Repin bass section with larger-size tuning pins.

Recondition ActionóRecondition action (clean & tighten screws, replace defective parts, replace bridle tapes hammers & treble damper felts.

Complete Cleaning--Clean cabinet interior, strings, pressure bar, keybed, keypins, pedal mechanisms.

Complete RegulationóInstall new felt underkey punchings. All regulation adjustments to ensure that piano plays like new. Adjust pitch & tune.

Selected pictures of the step-by-step improvement process

CLICK PICTURE FOR LARGER IMAGE, THEN CLICK "CLOSE" TO RETURN TO THIS PAGE

Original Manufacturer of this brand-name--Wm. Knabe & Gaehle.

Established--by William Knabe and Henry Gaehle, MD, 1837.

Other brand-names used by this manufacturer--The company was incorporated and in 1908 joined the American Piano Company. In 1932 Aeolian purchased American and formed the Aeolian-American Co. Knabe became part of the Mason & Hamlin Corp., along with Sohmer, Falcone and George Steck. In 1996 Young Chang started building Knabe pianos for Mason & Hamlin, and in 2002 Samick Music Corp. assumed production.

From: Pierce Piano Atlas, 12th Edition (2008, Larry Ashley Publisher, Albuquerque, NM).

Note: To obtain the age of your piano and details about the manufacturer, click: Pierce Piano Atlas--"the world's most authoritative publication on piano manufacturers, past and present." To learn how a piano works and how to go about buying one, we encourage you to purchase The Piano Book.

A - EVALUATION AND DISMANTLING AT OWNER'S HOME

For contact information, go to the "Home Page"

B - WORK COMPLETED IN THE SHOP

Selected pictures of the step-by-step improvement process

CLICK PICTURE FOR LARGER IMAGE, THEN CLICK "CLOSE" TO RETURN TO THIS PAGE

Cabinet is in original condition--exterior surfaces restored

|

A6 - Hammers Worn |

|

|

A7 - Bridle Tapes Worn |

|

|

A8 - Dampers Worn |

|

|

B1 - Strings cleaned |

|

|

B2 - Underkey felt punchings removed, keypins cleaned |

|

|

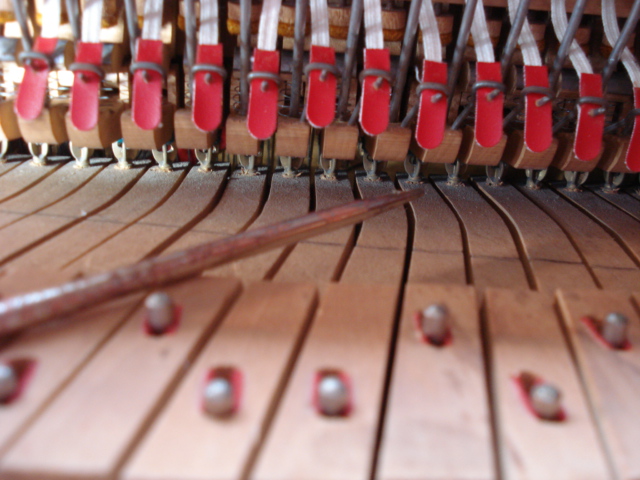

B3 - Damper levers and sustain bar removed |

|

|

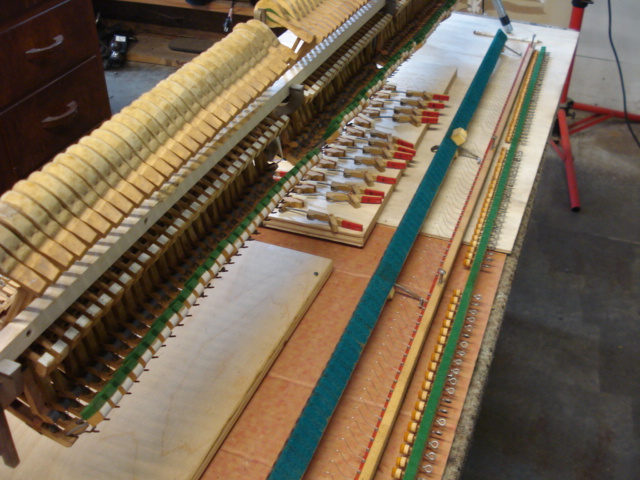

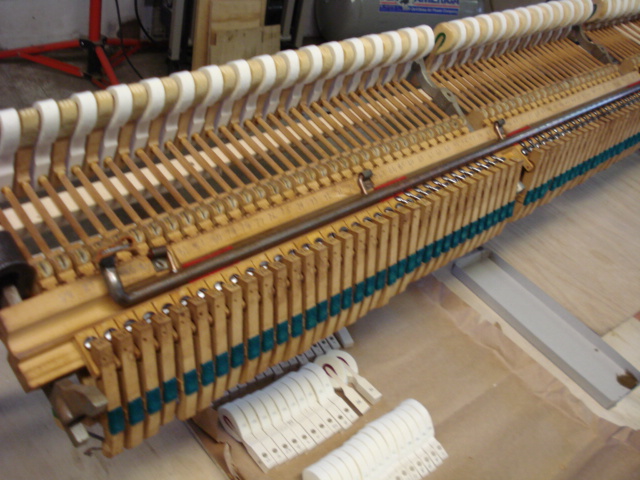

B4 - Hammer rail and regulating rail removed |

|

|

B5 - Pedal lyre cleaned and rebushed, bolt found to replace missing bolt |

|

|

B6 - White keys cleaned, replacements for chipped and missing keytops found and installed |

|

|

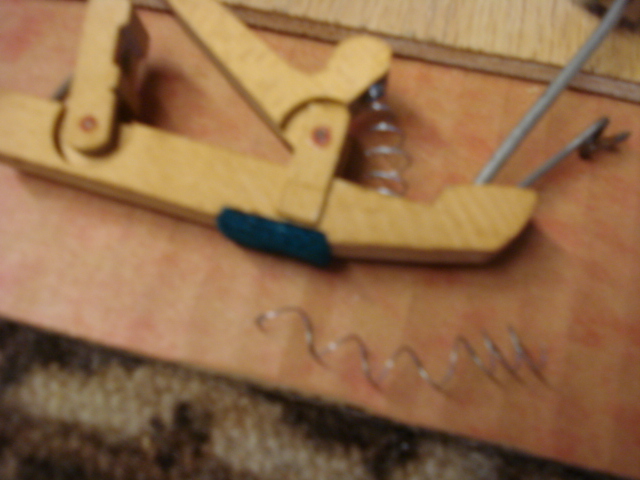

B7 - Twenty defective jack springs replaced |

|

|

B8 - All damper felts removed, damper blocks cleaned |

|

|

B9 - Odd-numbered original hammers removed |

|

|

B10 - Odd-numbered new hammers installed |

|

|

B11 - Several hammer shanks replaced |

|

|

B12 - Even-numbered original hammers removed |

|

|

B13 - Even-numbered hammers installed |

|

|

B14 - Hammer rail & regulating rail cleaned |

|

|

B15 - Spring rail cleaned |

|

|

B16 - Hammer rail & regulating rail re-installed |

|

|

B17 - Spring rail re-installed |

|

|

B18 - Sustain rail mechanism lubricated & re-installed |

|

C - WORK COMPLETED IN OWNER'S HOME

|

C1 - With piano on its back, AC glue installed in pinblock to increase tuning pin torque |

|

.JPG) |

C2 - Four strings installed with new tuning pins. (2) |

|

.JPG) |

C3 - Missing bolt in lyre support replace with new bolt. (2) |

|

|

C4 - Felt underkey punchings and bolster cloth replaced with new. |

|

|

C5 - Action installed |

|

|

C6 - Capstans regulated to eliminate lost motion |

|

|

C7 - Treble dampers regulated for even response to sustain pedal |

|

|

C8 - Bass dampers installed & regulated for even response to sustain pedal |

|

|

C9 - Letoff regulated & damper spoons regulated for even response to keystroke |

|

|

C10 - Key heights & leveling regulated with punchings & front keypin bender |

|

|

C11 - Key Dip regulated for even touch |

|

|

C12 - Ready for tuning |

|

|

C13 - Fallboard & keystop rail installed |

|

|

C14 - Music rest & lid installed |

|

|

C15 - Lower panel installed |

|

|

C16 - Project finished! To be checked & tuned in 3 months |

|