Current & Recent Projects

57 1/2" Strohber Upright #108857 (1909)

57 1/2" Strohber Upright #108857 (1909)

Traditional Mahogany Cabinet. Cabinet finish "refreshed" by a previous owner. Reconditioned in February, 2021 for the current owner in St. Cloud, MN.

IMPROVEMENTS:

Recondition ActionóInstall new pedals, hammers, shanks, butts, damper felts, underkey punchings. Replace worn backcheck felts and weak jack springs. Clean & tighten all action screws, replace other defective parts.

Complete Cleaning--Clean cabinet interior, strings, pressure bar, keybed, keypins, pedal mechanisms.

Complete RegulationóAll adjustments to ensure that piano plays like new. Adjust pitch & tune to A-440.

|

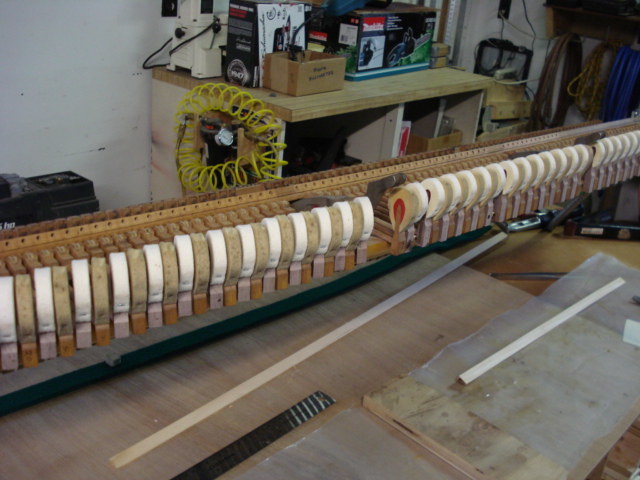

A1 Set Action on Workbench |

|

|

A2 Repair Music Desk |

|

|

A3 Install new music desk hinges |

|

|

A4 Install new music desk knobs |

|

Selected pictures of the step-by-step improvement process

CLICK PICTURE FOR LARGER IMAGE, THEN CLICK "CLOSE" TO RETURN TO THIS PAGE

Original Manufacturer of this brand-name--Smith, Barnes & Strohber, Chicago.

Established--as C.A. Smith & Co. at 1872 Clybourn, Chicago in 1891.

Other brand-names used by this manufacturer--Diminutive, Hoffmann, Lessing, Smith & Barnes, Strohber and Willard.

From: Pierce Piano Atlas, 12th Edition (2008, Larry Ashley Publisher, Albuquerque, NM).

Note: To obtain the age of your piano and details about the manufacturer, click: Pierce Piano Atlas--"the world's most authoritative publication on piano manufacturers, past and present." To learn how a piano works and how to go about buying one, we encourage you to purchase The Piano Book.

|

B1 New lid hinge pins installed |

|

|

B2 Inspecting broken pedals |

|

|

B3 Installing piano tilter |

|

|

B4 Tilting piano on its back for pedal replacement project |

|

A - IN OUR SHOP

For contact information, go to the "Home Page"

B - AT THE PIANO OWNER'S HOME

Selected pictures of the step-by-step improvement process

CLICK PICTURE FOR LARGER IMAGE, THEN CLICK "CLOSE" TO RETURN TO THIS PAGE

An elegant vintage piano--a real pleasure to recondition!

|

A5 Clean all keys, replace missing and chipped keytops |

|

|

A6 Remove bridle tapes & regulating rail |

|

|

A7 Remove dampers & hammer spring rail, tighten all action screws |

|

|

A8 Reglue loose jack |

|

|

A9 Repair end block |

|

|

A10 Cut off 7 warped hammer shanks |

|

|

A11 Install 7 new hammer shanks |

|

|

A12 Remove worn catcher leader in mid-section |

|

|

A13 Install new catcher leather in mid-section |

|

|

A14 Clean & lubricate regulating rail |

|

|

A15 Replace broken regulating button |

|

|

A16 Remove treble damper pads |

|

|

A17 Sand damper blocks |

|

|

A18 Replace broken damper lever flange |

|

|

A19 Remove hammer rail cloth |

|

|

A20 Strengthen & clean hammer rail springs |

|

|

A21 Remove old evens hammers, clean shanks. |

|

|

A22 Install new evens hammers, align to old odds hammers |

|

|

A23 Remove old odds hammers, clean shanks |

|

|

A24 All New hammers installed |

|

|

A25 Regulating rail re-installed |

|

|

A26 Bridle tapes connected to wippens |

|

|

A27 Bridle tapes glued in place |

|

|

A28 Damper levers re-installed, new damper felts glued on damper blocks. Action reconditioning project completed! |

|

|

B5 Pedal board removed |

|

|

B6 Positioning new middle pedal |

|

|

B7 Pedal board with new pedals ready for re-installation |

|

|

B8 - Close-up of new pedals |

|

|

B9 - Massive frame and harp--in very good condition |

|

|

B10 - New Lid hinge pins installed, molding repair |

|

|

B11 - New underkey punchings installed |

|

|

B12 - New underkey punchings and cloth installed |

|

|

B13 Loki, the owner's cat, was a frequent visitor during regulation and reassembly |

|

|

B14 Complete regulation & tuning--hammer blow distance, capstans, dampers, key heights & leveling, hammer alignment to strings, key dip. . . |

|

|

B15 - Music desk, fallboard, lower panel installed - PROJECT COMPLETE! |

|

|

B16 - Close-up of keyboard & decal |

|