Current & Recent Projects

Wurlitzer Spinet, 1971

36" Wurlitzer (Melville Clark) Spinet, 1971

Traditional Walnut Cabinet. Built about 1971. Reconditioned and regulated in September, 2013 for the owner in Monticello, MN.

IMPROVEMENTS:

Recondition ActionóTighten all action screws. Align hammers to strings. Reshape hammers.

Complete Cleaning--Clean strings, pressure bar, keybed, keypins, pedal mechanisms.

Complete RegulationóAll adjustments to ensure that piano plays like new, tune to A-440.

Selected pictures of the step-by-step improvement process

CLICK PICTURE FOR LARGER IMAGE, THEN CLICK "CLOSE" TO RETURN TO THIS PAGE

Original Manufacturer of this brand-name--Wurlitzer Co., New York.

Established--1856 in New York. 1861 in Cincinnati.

Other brand-names used by this manufacturer--Apollo, Julius Bauer & Co., Melville Clark, De Kalb, Farney, Kingston.

From: Pierce Piano Atlas, 12th Edition (2008, Larry Ashley Publisher, Albuquerque, NM).

Note: To obtain the age of your piano and details about the manufacturer, click: Pierce Piano Atlas--"the world's most authoritative publication on piano manufacturers, past and present." To learn how a piano works and how to go about buying one, we encourage you to purchase The Piano Book.

When we visited this piano, we found that very little maintenance work had been completed since it was new. Hammers were badly worn and, worse, the hammer shanks had warped considerably, resulting in a number of hammers no longer striking the strings squarely. Another issue was the looseness of the action screws--they were so loose that the dampers hardly lifted when the keys were struck. Also, the regulation was so badly out of adjustment that the touch was severely affected--many keys required very hard key strokes to respond. These issues could be addressed in less than two days' work, and the owner was very pleased with the result.

|

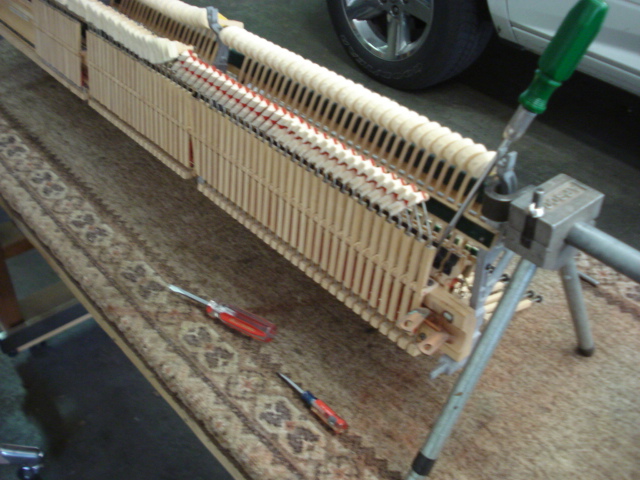

13 - Action on work bench |

|

|

14 - Clean action with compressed air |

|

|

15 - Tighten all action screws |

|

|

16 - Make striking point pattern |

|

|

9 - Panels and Keys in storage |

|

|

10 - Remove action with capstans held up |

|

|

11 - Install treble string |

|

|

12 - Stringing tools |

|

|

17 - Striking point pattern close-up |

|

|

18 - Treble hammers aligned to strings |

|

|

19 - Shank-bending pliers and glue heater |

|

|

20 - Bass hammers aligned to strings |

|

|

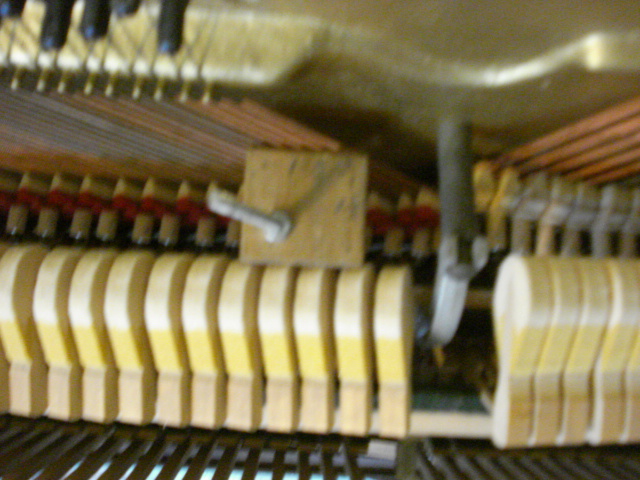

21 - Catcher wires regulated |

|

|

22 - Hammers reshaped |

|

|

27 - Key heights regulated |

|

|

28 - Key leveling regulated |

|

|

29 - Sharp heights regulated |

|

|

30 - Keydip regulated |

|

|

31 - Sharp dip regulated |

|

|

32 - Re-assembled |

|

A - IN THE CLIENT'S HOME

|

5 - Measure action ratio |

|

|

6 - Make striking point pattern |

|

|

7 - Remove capstans |

|

|

8 - Remove keys |

|

|

1 - In client's home |

|

|

2 - Panels & covers removed |

|

|

3 - Measre hammer blow distance |

|

|

4 - Hammers poorly aligned to strings |

|

B - IN OUR WORKSHOP

|

23 - Action replaced & spoons regulated |

|

|

24 - Capstans & letoff regulated |

|

|

25 - Keys cleaned |

|

|

26 - Key wobble reduced |

|

C -BACK IN CLIENT'S HOME

Our shop is located in Becker, Minnesota. For contact information, go to the "Home Page"